Bell Racing

Bell Racing

WHAT DEFINES BELL RACING AS A MAJOR SOURCE FOR AUTO AND KART RACING

65 years of innovation, with a design philosophy that prioritizes function over form. Each product is purpose built for the application. Bell takes a minimalistic approach to product development. They construct purely for driver safety, and with features to enhance driver performance and protection. Designs are developed and perfected through direct feedback from the world’s best athletes and race teams ensuring reliable performance in the most demanding racing environments and conditions.

INTRODUCING WHAT DEFINES BELL RACING AS A MAJOR SOURCE FOR AUTO AND KART RACING

65 + years of innovation, with a design philosophy that prioritizes function over form. Each product is purpose built for the application. Bell takes a minimalistic approach to product development. They construct purely for driver safety, and with features to enhance driver performance and protection. Designs are developed and perfected through direct feedback from the world’s best athletes and race teams ensuring reliable performance in the most demanding racing environments and conditions.

3D DESIGN & ENGINEERING

Bell makes extensive use of advanced 3D modeling, computer aided design (CAD) and rapid prototyping to drive product innovation and reduce the time needed to develop and deliver new products. This allows Bell to conceptualize and refine the design, assure physical dimensions and component integration, conduct strength and dynamic analysis, predict impact performance, produce precise renderings, and confirm manufacturing process details before developing prototypes or producing physical tooling.

3D DESIGN & ENGINEERING

Bell makes extensive use of advanced 3D modeling, computer aided design (CAD) and rapid prototyping to drive product innovation and reduce the time needed to develop and deliver new products. This allows Bell to conceptualize and refine the design, assure physical dimensions and component integration, conduct strength and dynamic analysis, predict impact performance, produce precise renderings, and confirm manufacturing process details before developing prototypes or producing physical tooling.

TESTING & DEVELOPMENT

Bell does extensive, ongoing research and development testing to assure the best possible combination of materials and manufacturing techniques to deliver products that maximize energy management and driver protection while ensuring they exceed the most stringent helmet standards in motorsports. Bell collaborates extensively with suppliers, racing series and safety organizations including FIA, Snell and SFI to continue to advance helmet safety and performance.

TESTING & DEVELOPMENT

Bell does extensive, ongoing research and development testing to assure the best possible combination of materials and manufacturing techniques to deliver products that maximize energy management and driver protection while ensuring they exceed the most stringent helmet standards in motorsports. Bell collaborates extensively with suppliers, racing series and safety organizations including FIA, Snell and SFI to continue to advance helmet safety and performance.

FUNCTION & PERFORMANCE

Bell’s goal when designing a helmet is to optimize shell and liner performance to limit the energy forces transmitted to the driver’s head during an impact in a configuration that minimizes volume and weight. This is achieved by combining a high-strength outer shell to maintain structural integrity and limit penetration with a multi-density inner liner system that absorbs energy and a retention system that assures the helmet is properly fitted to the driver’s head.

FUNCTION & PERFORMANCE

Bell’s goal when designing a helmet is to optimize shell and liner performance to limit the energy forces transmitted to the driver’s head during an impact in a configuration that minimizes volume and weight. This is achieved by combining a high-strength outer shell to maintain structural integrity and limit penetration with a multi-density inner liner system that absorbs energy and a retention system that assures the helmet is properly fitted to the driver’s head.

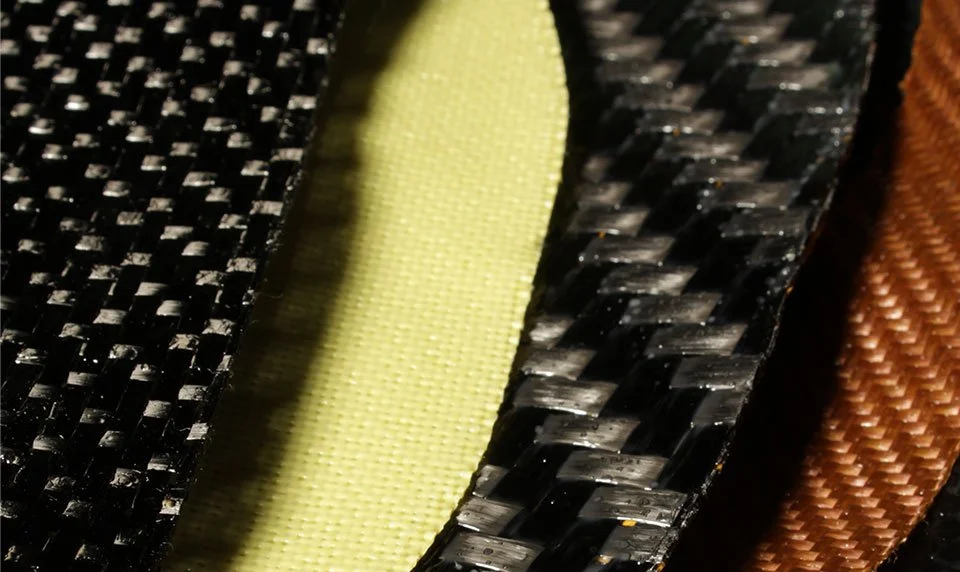

ADVANCED MATERIALS

Bell uses modern components and the latest materials from ISO* certified suppliers in the United States and Europe to create advanced designs. The shell is made using pre-impregnated (pre-preg) composite and aerospace grade carbon materials with precise resin to fabric ratios. This assures consistency and performance. The liner system (crush zone foam) is molded on site, using a proprietary EPS (expanded polystyrene) formulation. This EPS has a natural rebound for impact mitigation and prevent serious head injuries. Bell selects only the highest quality performance interior fabrics to assure comfort, perspiration management with excellent fire-retardant properties.

*ISO STANDARDS ARE INTERNATIONALLY AGREED BY EXPERTS

ADVANCED MATERIALS

Bell uses modern components and the latest materials from ISO* certified suppliers in the United States and Europe to create advanced designs. The shell is made using pre-impregnated (pre-preg) composite and aerospace grade carbon materials with precise resin to fabric ratios. This assures consistency and performance. The liner system (crush zone foam) is molded on site, using a proprietary EPS (expanded polystyrene) formulation. This EPS has a natural rebound for impact mitigation and prevent serious head injuries. Bell selects only the highest quality performance interior fabrics to assure comfort, perspiration management with excellent fire-retardant properties.

*ISO STANDARDS ARE INTERNATIONALLY AGREED BY EXPERTS

MODERN CONSTRUCTION TECHNIQUES

Bell uses the latest manufacturing techniques using a proprietary molding system that combines high-temperature and high-pressure to create a strong, ultra-lightweight outer shell. The pre-preg materials are applied onto a silicone bladder that matches the helmet design, the bladder is inserted into an aluminum tool and the shell is cured using heat, pressure and time. Bell’s energy absorbing liner system is molded in-house and features a multi-piece design with a strong outer ring for structural support, inner and outer inserts that can be molded in multiple densities, and other reinforcement materials to optimize impact management and performance based.

MODERN CONSTRUCTION TECHNIQUES

Bell uses the latest manufacturing techniques using a proprietary molding system that combines high-temperature and high-pressure to create a strong, ultra-lightweight outer shell. The pre-preg materials are applied onto a silicone bladder that matches the helmet design, the bladder is inserted into an aluminum tool and the shell is cured using heat, pressure and time. Bell’s energy absorbing liner system is molded in-house and features a multi-piece design with a strong outer ring for structural support, inner and outer inserts that can be molded in multiple densities, and other reinforcement materials to optimize impact management and performance based.

3D HEAD SCAN for a custom fit

Bell works with top sponsored athletes to improve helmet fit by taking a 3D head scan of the driver and then building a custom interior. The process starts with a custom head scan to create an exact 3D model of the driver’s head shape. Bell’s engineering team uses computer aided design (CAD) to position the scan within the parameters of the inner liner. Using this data, a custom interior is built, precisely duplicating the driver’s head shape to create a secure, perfect fit that eliminates all pressure points and promotes comfort.

3D HEAD SCAN for a custom fit

Bell works with top sponsored athletes to improve helmet fit by taking a 3D head scan of the driver and then building a custom interior. The process starts with a custom head scan to create an exact 3D model of the driver’s head shape. Bell’s engineering team uses computer aided design (CAD) to position the scan within the parameters of the inner liner. Using this data, a custom interior is built, precisely duplicating the driver’s head shape to create a secure, perfect fit that eliminates all pressure points and promotes comfort.

AERODYNAMICS

Bell’s extensive 65 year history of manufacturing helmets gives them the expertise to develop shells that provide aerodynamic stability and performance at high-speeds. Their designs minimize the helmet’s aerodynamic signature and reduce acoustic interior noise. Bell uses a combination of shell design and performance features including front chin gurneys, top gurneys and rear spoilers to increase downforce, reduce buffeting and lift and increase helmet stability.

Bell’s extensive 65 year history of manufacturing helmets gives them the expertise to develop shells that provide aerodynamic stability and performance at high-speeds. Their designs minimize the helmet’s aerodynamic signature and reduce acoustic interior noise. Bell uses a combination of shell design and performance features including front chin gurneys, top gurneys and rear spoilers to increase downforce, reduce buffeting and lift and increase helmet stability.

VENTILATION

Bell maximizes helmet ventilation with internal vent systems that direct airflow to the driver’s head, This enhances driver cooling and comfort plus helps reduce shield fogging.

VENTILATION

Bell maximizes helmet ventilation with internal vent systems that direct airflow to the driver’s head, This enhances driver cooling and comfort plus helps reduce shield fogging.

DSAF INSERT TECHNOLOGY

Unique to the racing industry, Bell was the first company to integrate a Double Screen Anti Fog Insert (DSAF) into the shield. The DSAF shield is sealed with a synthetic rubber gasket. The DSAF insert creates an air-barrier between the outer shield and inner shield to eliminate interior fogging and is especially effective in high-temperature, high-humidity environments. The double visor prevents fogging and the rubber seal around the visors exterior prevents air, water and dust from entering the helmet.

DSAF INSERT TECHNOLOGY

Unique to the racing industry, Bell was the first company to integrate a Double Screen Anti Fog Insert (DSAF) into the shield. The DSAF shield is sealed with a synthetic rubber gasket. The DSAF insert creates an air-barrier between the outer shield and inner shield to eliminate interior fogging and is especially effective in high-temperature, high-humidity environments. The double visor prevents fogging and the rubber seal around the visors exterior prevents air, water and dust from entering the helmet.

CUSTOM PAINT AND GRAPHICS

Apply custom paint to a helmet can add a tremendous amount of weight finished helmets’ weight. Bell had developed specific and precise in-house custom paint procedures and graphic techniques that limit this additional weight to 40-60 grams, keeping the helmet as light as possible.

CUSTOM PAINT AND GRAPHICS

Apply custom paint to a helmet can add a tremendous amount of weight finished helmets’ weight. Bell had developed specific and precise in-house custom paint procedures and graphic techniques that limit this additional weight to 40-60 grams, keeping the helmet as light as possible.